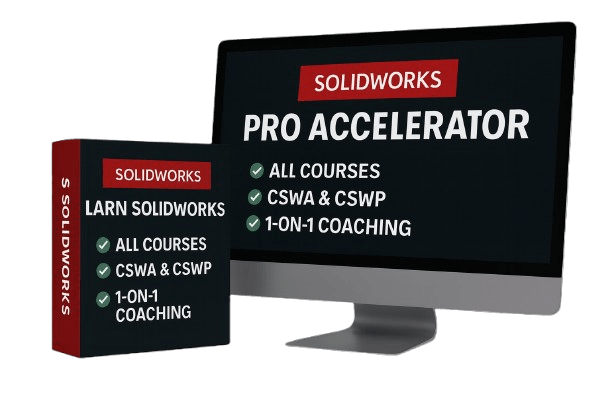

SolidWorks PRO Accelerator

Become a top-tier SolidWorks designer in 8–12 weeks. Build a real portfolio. Earn certifications. Develop job-ready skills.

A step-by-step training designed to take you from uncertain beginner to confident, certified, hire-ready SolidWorks designer — even if you don’t know where to start, or you’ve failed to learn from YouTube or courses before.

9

Courses

30+

Hours Video Material

50+ Examples

60+ Exercises

If you are on this site, there’s a pretty good chance you’re still trying to figure this out SolidWorks.

Maybe you’ve tried YouTube tutorials.

Maybe you took a course or two.

Maybe you understand some tools…

But when you sit down to model a real part —

You freeze.

You delete.

You start over.

You second-guess everything.

And eventually that thought creeps in:

“Maybe I’m just not good enough at SolidWorks.”

But listen carefully:

The problem is NOT you.

The problem is the way you’ve been trying to learn.

Most beginners learn SolidWorks in random pieces:

One tutorial here…

Another trick there…

A cool feature over here…

So sure, you learn tools.

But you never learn workflow.

And so when you're faced with a real model, something that doesn’t come with perfect dimensions, or a step-by-step explanation, you don’t know where to start.

Not because you lack skill.

But because you lack structure.

And here’s the truth no one tells beginners:

If you’re not in the top 15% of SolidWorks users…

You are invisible in the job market.

There are thousands of people “who kind of know SolidWorks.”

They never get hired.

They never get promoted.

They never get trusted.

Because employers don’t want “kinda.”

They want...

Confidence

Skill

Proof

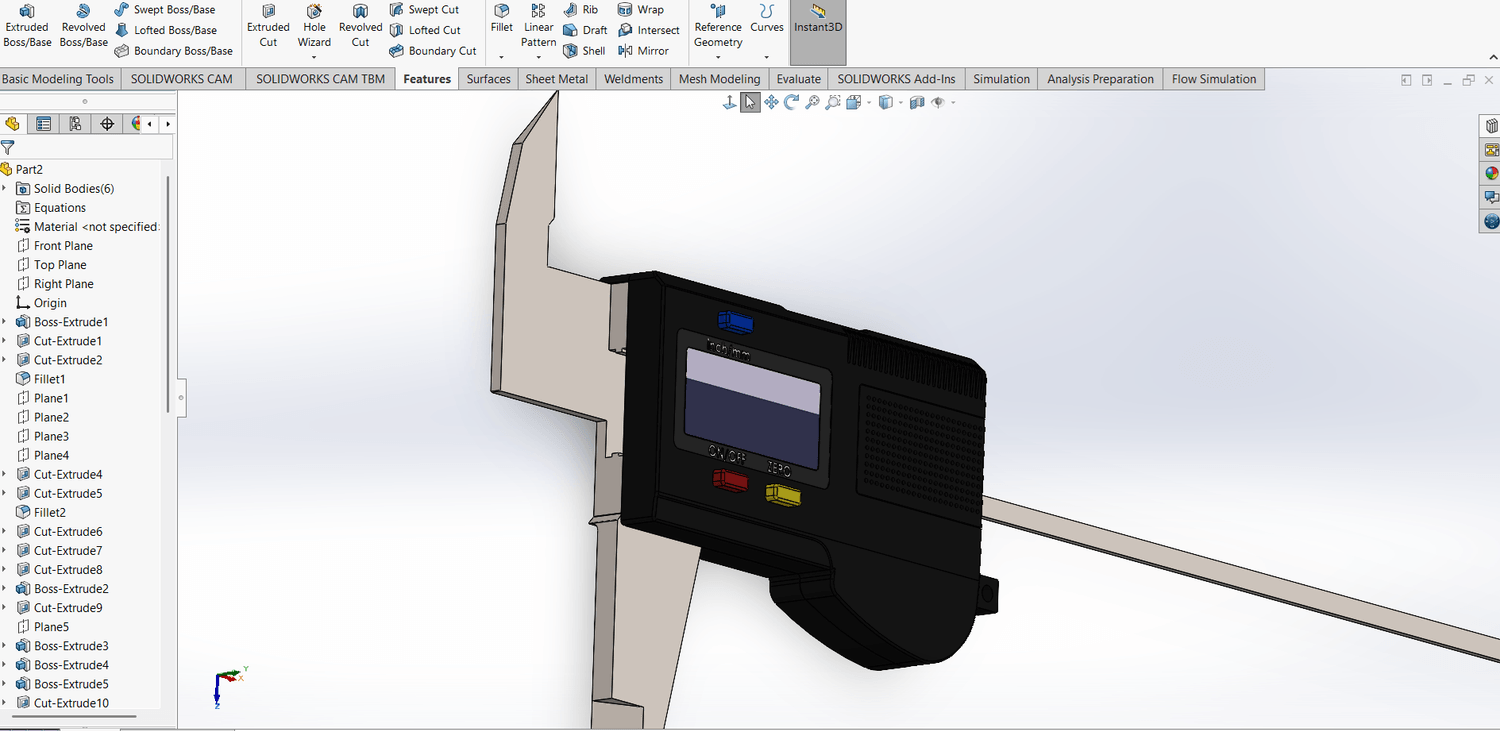

They want someone who can model real parts cleanly.

Who can assemble real mechanisms.

Who can create real drawings that manufacturers understand.

And most importantly...

Someone who can do it without being hold by the hand.

This is WHAT SolidWorks PRO Accelerator is made for.

Let's get clear who this program is for

This program is NOT for:

SolidWorks advanced users looking for advanced tips and tricks

People who expect results without following a structured learning path

Who This Is For

Students & graduates who want a clear skill advantage for job applications

Technicians, engineers, and designers who want to level up and earn more

Freelancers who want to offer professional CAD services and build client trust

Anyone who wants to finally feel confident modeling real-world parts, assemblies, and drawings

What You'll be Able To Do After Finishing The Course?

Now imagine yourself 8–12 weeks from now.

You open SolidWorks…

And instead of guessing…

You know exactly what to do.

Imagine...

Be able to model real, manufacturable parts from scratch

Build complex assemblies using professional workflows

Produce accurate technical drawings used in manufacturing

Pass the CSWA & CSWP certification exams with confidence

Build a portfolio of real projects you can show employers

Think like a designer, not just a software user

Know how to work independently on real engineering tasks

Why We Are Different?

We’ve made it simple to succeed:

You don’t need to struggle through random tutorials or guess what to learn next. You get:

Clear, linear video lessons (no fluff)

Downloadable practice files

Ready-to-use project templates

All content in one place, accessible anytime

No deadlines. No confusion. No wasted time.

You just open the lesson, follow the steps, and build real-world projects on your own time.

What’s Inside (Full Breakdown)

1. SolidWorks Essentials (Beginner → Intermediate): Foundation of professional modeling.

Sketching fundamentals

Constraints & design intent

Solid modeling workflows

Modifying and improving existing designs

2. SolidWorks Advanced Design: Clean, efficient modeling like engineers do in real projects.

Multi-body workflows

Configurations

Design tables

Performance & feature optimization

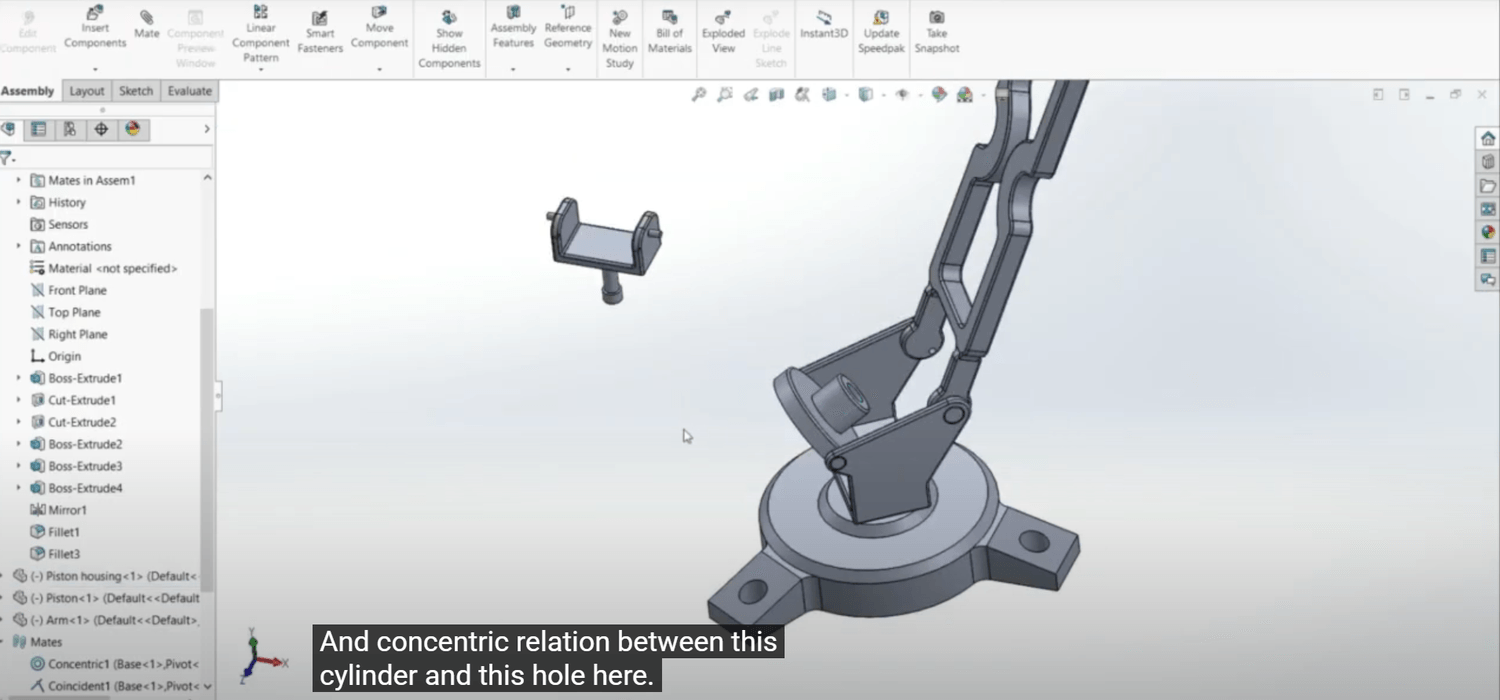

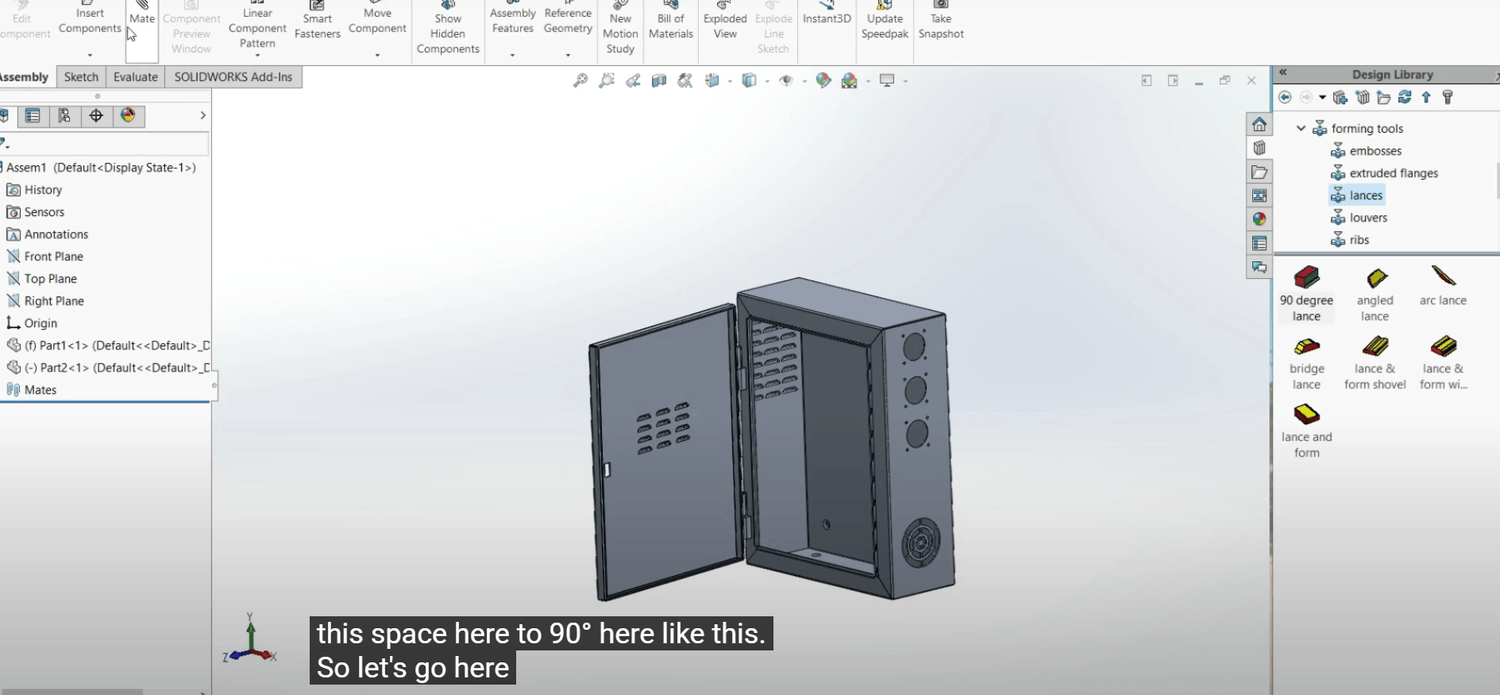

3. Assembly Design Mastery: Understand how real products come together.

Bottom-up & top-down workflows

Mates that behave predictably

Subassemblies

Motion setup & troubleshooting

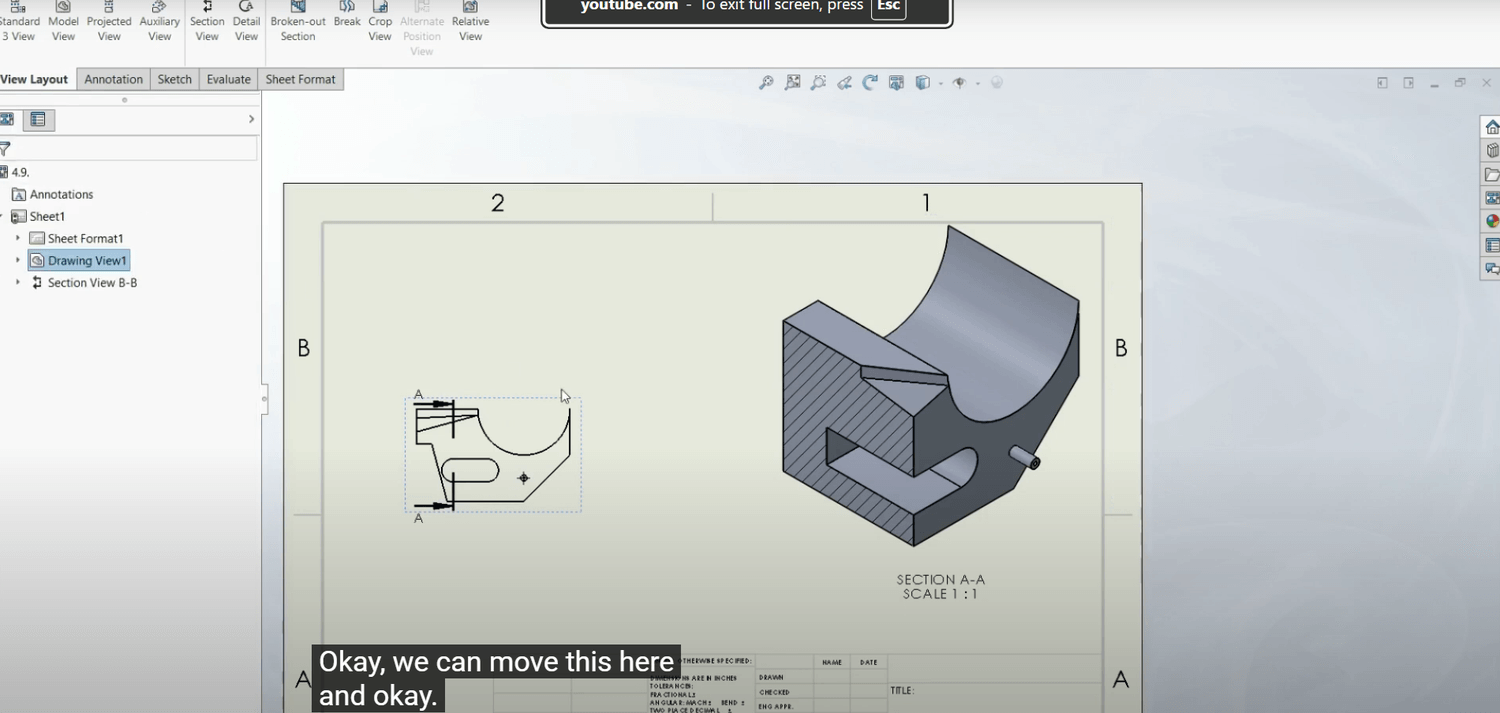

4. Drawing & Manufacturing Documentation: Turn models into real, buildable parts.

Dimensioning standards

GD&T basics

Bill of Materials & exploded views

Production-ready drawing layout

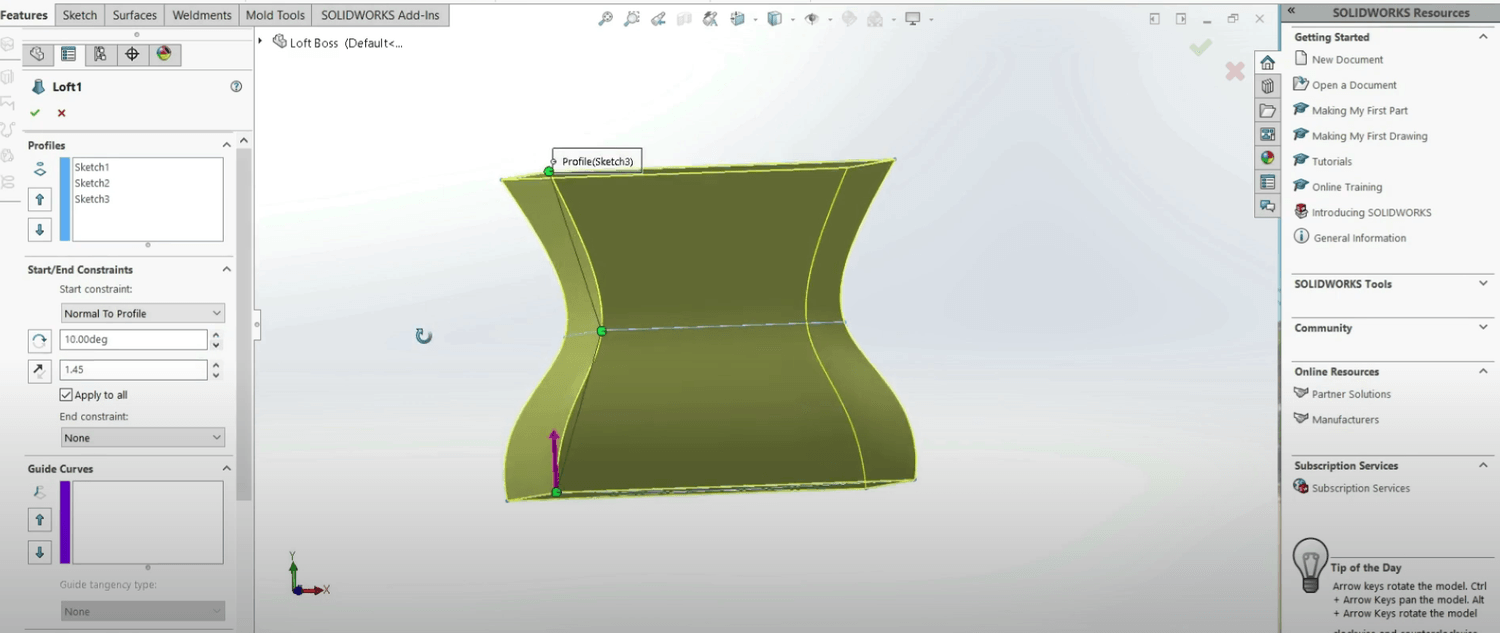

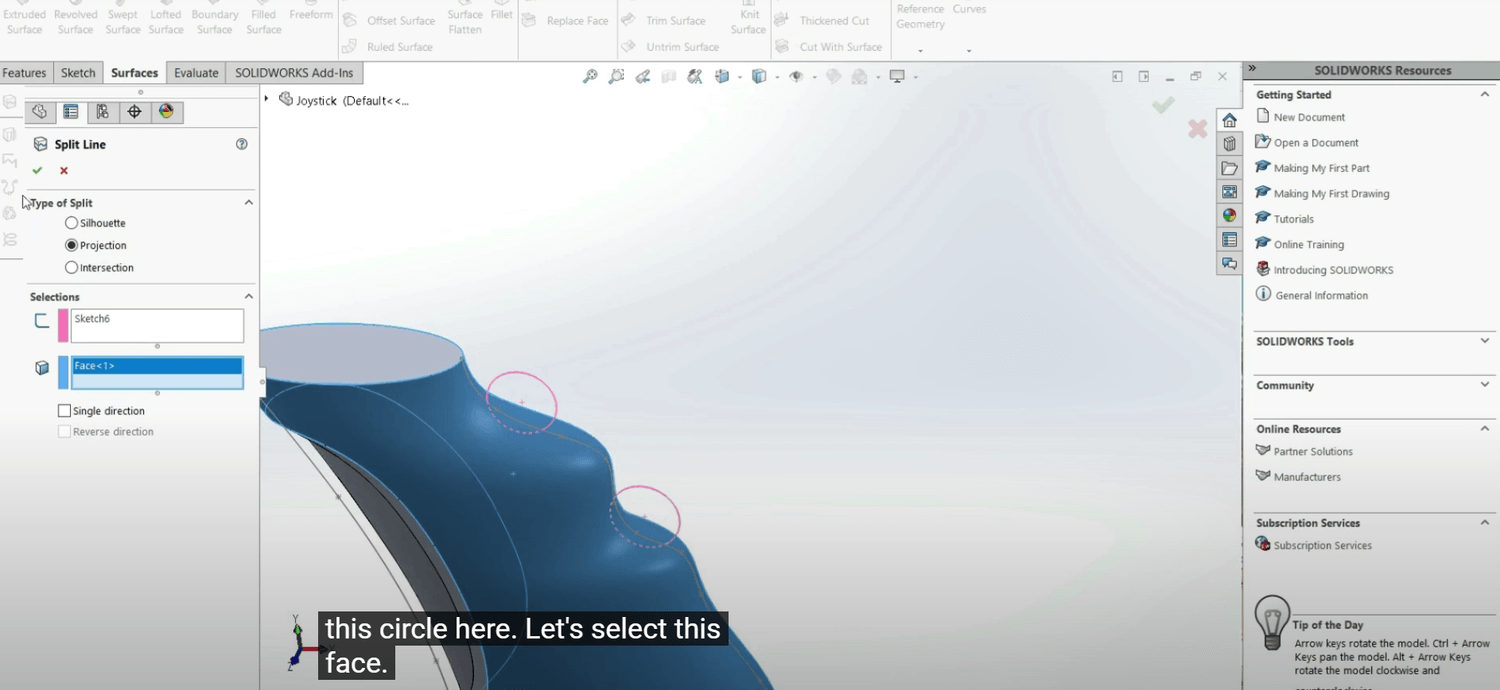

5. Surfacing: Industry-critical advanced skillsets.

Organic & freeform surfacing

Proper shelling, filleting & curvature control

6. Sheet Metal: Industry-critical advanced skillsets.

Sheet metal bends, reliefs & flat patterns

Real-world manufacturability principles

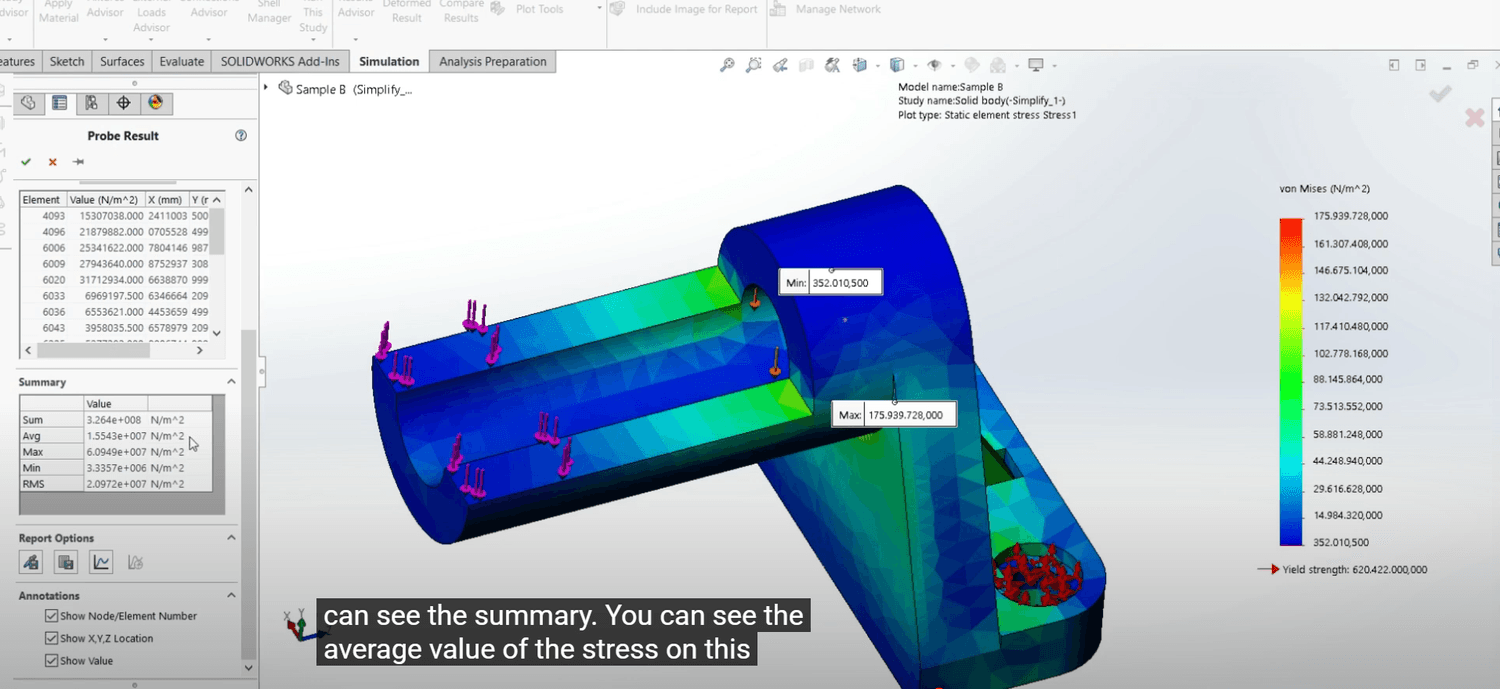

7. FEA Simulation (Static Analysis): Analyze parts before manufacturing.

Applying loads & boundary conditions

Mesh refinement & accuracy

Stress & deformation interpretation

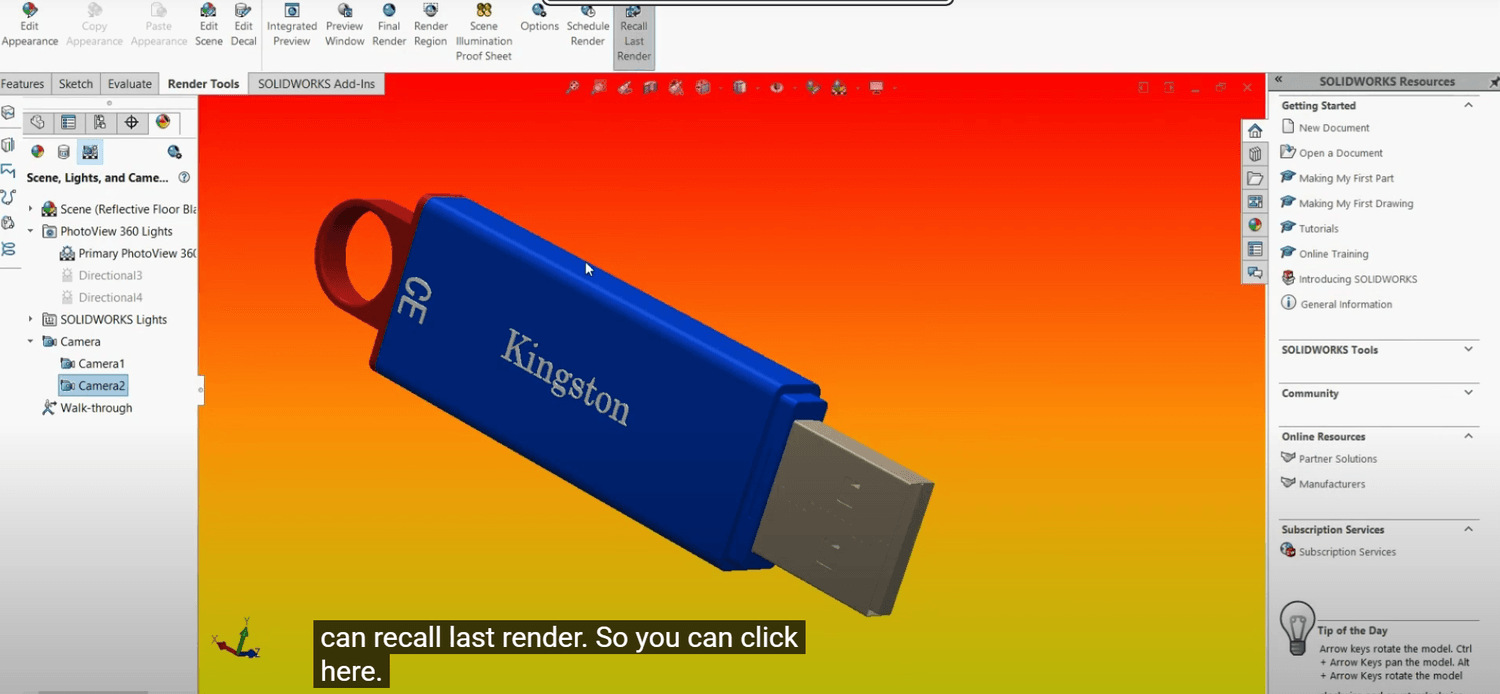

8. Rendering & Animation: Make your work look professional.

Realistic studio lighting & materials

Photorealistic product renders

Exploded motion & assembly animations

9. Evaluation Tools & Design Validation: Design smarter, not harder.

Mass properties

Interference checks

Draft analysis & manufacturability checks

10. Certification Prep: CSWA + CSWP: Everything you need to pass — confidently.

Full breakdowns of exam tasks

Time-saving modeling strategies

Practice tests

“Pass Checklist” to eliminate mistakes

If you’re ready to:

Build real skill

Build confidence

Build a portfolio

Become a certified SolidWorks professional

And finally feel like the engineer you know you can be

Here’s What You Get Lifetime Access To:

9 Complete Courses (35+ hours material) [$900]

50+ Real-World Examples [$200]

60+ Practical Exercises [$150]

2 SolidWorks Certification Preps [$100]

Portfolio projects [$250]

Private Community Support [$500]

TOTAL VALUE: $2000

Today you get it for ONLY:

Option 1 — Payment Plan

$197 × 3 monthly payments

Option 2 — Pay in Full (Save $100)

$497 one time payment

Guarantee

30-Day “Skill Progress” Guarantee

If you go through the lessons, practice the exercises, and don’t feel your modeling skill improving, email me and I’ll refund you. No questions.

Why Listen to Me

I’m Alen Oletic, Mechanical Engineer (MSc), SolidWorks Certified Professional.

48,000+ students trained worldwide

Average 4.5/5 course rating

Former industrial machine design engineer

Teaching SolidWorks daily for 4+ years

I’ve helped:

Students land first engineering jobs

Designers pass CSWA/CSWP

Engineers gain confidence in real-world modeling

This works because it's structured, not random.

Why This Matters Right Now

Basic SolidWorks skills are getting automated.

AI can already:

Generate simple parts

Suggest features and fillets

Copy existing designs

Which means…

If you only click buttons and make basic design, your work becomes replaceable.

But here’s the key:

AI cannot replace people who think like designers.

It cannot:

Decide what’s manufacturable

Design for assembly

Select tolerances

Validate stress or failure risk

Communicate real engineering intent

Those are the skills that get you hired, promoted, and paid more.

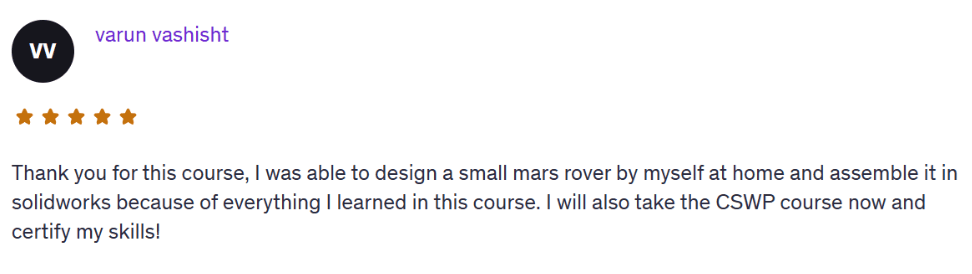

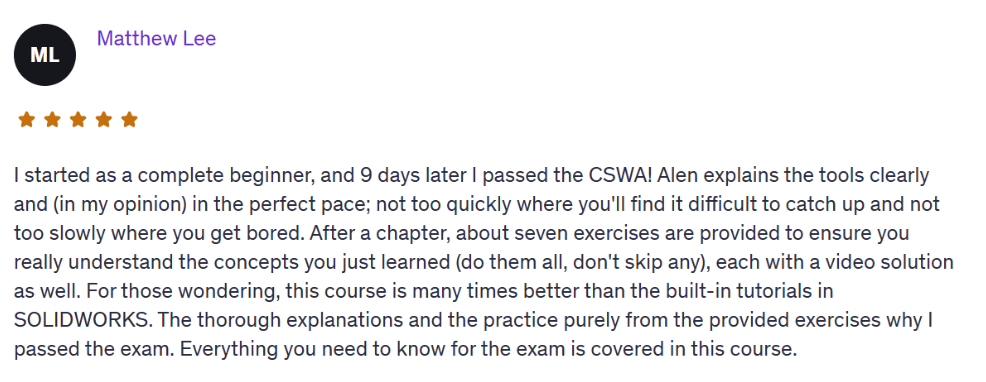

See What Our Students Are Saying

Every month you don’t master SolidWorks, someone else gets ahead of you.

Someone else gets certified.

Someone else gets the job.

Someone else gets the salary.

Someone else gets the confidence you wish you had.

Skills are the currency of engineering.

And right now, your competition is learning while you are deciding.

Don’t let another year slip away.

More From Our Students

Frequently Asked Questions

No. The SolidWorks PRO Accelerator starts from absolute beginner level and guides you step-by-step to advanced tools. You’ll master everything from sketches and parts to full assemblies and simulations.

Most students complete it in 8–12 weeks, depending on how much time they dedicate weekly. You get lifetime access, so you can learn at your own pace and return anytime.

No, but we show you how to get a free trial or educational license directly from Dassault Systèmes if you’re a student or learning independently.

Yes, you’ll receive a personalized Certificate of Completion.

You'll have lifetime access to the community where you can ask any questions on daily basis.

Absolutely. Many students use this program to build a real portfolio and land jobs or freelance clients. You’ll learn the same workflows used in professional mechanical design roles.

Yes. You get lifetime access to all modules, files, and updates. You can log in anytime and learn at your own pace, from anywhere in the world.

Go from unsure beginner → confident designer without guessing your way through YouTube.

COURSE OUTLINE

COURSE 1 + COURSE 2: SOLIDWORKS ESSENTIALS + CSWA PREP

Creating a New File

User Interface

Mouse Movement

Opening/Saving Document

Creating A Sketch On The Standard Plane

Standard Sketch Tools

Fully/Over/Under Defined Sketch

Sketch Relations

Sketch Dimensions

Driving vs Driven Dimensions

Trim/Extend

Offset Entities

Mirror Entities

Linear And Circular Sketch Pattern

Edit Sketch

Properties And Units

Convert Sketch To 3D Model

Sketch On The Face

New Plane Creation

Convert Entities

3D Sketch

Heads-Up View Toolbar

Example 1

Example 2

Exercises

Extruded Boss Start/End Conditions

Extruded Cut Start/End Conditions

Extruded Boss/Cut Direction Vector

Extruded Boss -Thin Feature

Fillet And Chamfer

Rib

Draft

Shell

Part Modifications

Example 1

Example 2

Exercises

Material And Density

Global Variables And Linked Dimensions

Equations

Mass Properties And Coordinate System

Measuring Tool

Example 1

Example 2

Exercises

Mirror

Revolved Boss/Cut

Swept Boss

Swept Cut

Lofted Boss

Lofted Cut

Example 1

Example 2

Exercises

Inserting Components

Move Components

Standard Mates

Mirror Components

Collision Detection

Example 1

Example 2

Exercises

Setting Up A Drawing Sheet

Orthographic Views

View Properties And Projected View

Smart Dimensions And Units

Model Items - Part

Model Items - Assembly

Edit Sheet

Multiple Sheets

Saving Options

Example 1

Example 2

Exercises

Auxiliary View

Section View

Detail View

Broken-Out Section View

Break View

Crop View

Alternate Position View

Exercises

Download Exam

Video Tutorial 1

Video Tutorial 2

COURSE 3 + COURSE 4: SOLIDWORKS ADVANCED + CSWP PREP

Feature Conditions

Draft

Typed of Drafts

Shell

Multi-body Part

Mirror

Rib

Hole Wizard

Feature Scope

Linked Dimensions

Equations

Reference Geometry And Mass Properties

Sample Exam Segment 1

Design Table Creation

Design Table Modification

Configurations

Sample Exam Segment 2

Distance And Angle

Profile Center

Symmetric And Width

Collision And Interference Detection

Replacing Part

Measuring Tool

Linear/Linear Coupler

Assembly Features

Sub-assembly

Sample Exam Segment 3

Segment 1

Segment 2

Segment 3

COURSE 4: SOLIDWORKS DRAWING MASTERY + CSWPA-DT Prep

Setting Up A Drawing Sheet

Orthographic Views

View Properties And Projected View

Driving vs Driven Dimensions

Driving Dimensions

Driven Dimensions

Ordinate Dimensions

Angular Dimensions

Chamfer Dimensions

Model Item - Assembly

Dimension Properties

Dimension Style

Document Properties

View Focus

Custom Type View

3D Drawing View Tool

Predefined View

Relative View

Section View

Auxiliary View

Detail View

Broken-out Section View

Break View

Alternate Position View

Crop View

Isometric Section View

Measuring Tool

Dimension Rounding

Convert View

Centermark And Centerline

Hole Callout

Surface Finish

Weld Symbols

Hatch Pattern

Exploded View

Balloon And Magnetic Line

Autoballoon

Hole Table

Bill of Materials Table (BOM)

BOM Sorting And Item Numbers

Missing Item In BOM

Custom Properties

Equations

Show/Hide Components

Linked Notes

Generate Table

Layers

Multiple Sheets

Edit Sheet

Sheet Properties

Saving Options

Download Exam

Question 1

Question 2

Question 3

Question 4

Question 5

Question 6

COURSE 5: SOLIDWORKS SURFACING MASTERY + CSWPA-SU PREP

3D Sketch

Spline

Split Surface

Extruded Surface

Extruded Surface Open Sketch

Extruded Surface Start Conditions

Extruded Surface End Conditions

Face Extrusion

Revolved Surface Variations

Swept Surface

Swept Surface Guided Curves

Swept Surface Orientation and Twist

Curvature Display

Lofted Surface

Lofted Surface Connectors

Lofted Surface Guide Curves

Lofted Surface Centerline Parameter

Lofted Surface Strart/End Conditions

Boundary Surface

Boundary Surface Advantages

Boundary Surface Example

Filled Surface

Filled Surface Control

Filled Surface Using Edge

Optimizing Filled Surface

Ruled Surface

Ruled Surface Options

Offset Surface

Planar Surface

Bowl

Candle Holder

Trim Surface

Trim Surface Types

Trim Surface Advanced Options

Untrim Surface

Untrim Surface Advanced Options

Cut With Surface

Delete Face

Delete Face Options

Extend Surface

Knit Surface

Replace Face

Thicken Tool

Thicken Cut

Fillet

Direct Editing - Move

Freeform Tool

Freeform Continuity Options

Freeform Control Curve

Freeform Control Points

Freeform Symmetry

Freeform Precise Control

Flatten Surface

Bottle

Shovel

Joystick

Vintage Plane

Download Exam

Question 1

Question 2

Question 3

Question 4

COURSE 6: SOLIDWORKS SHEET METAL MASTERY

Base Flange - Thickness And Bend Radius

Feature Manager Design Tree

Gauge Tables

Bend Allowance

Auto-relief

Edge Flange

Edge Flange - Length And Position

Tab Feature

Extruded Cut And Hole

Miter Flange

Sketched Bend

Jog Bend

Hem

Cross Break

Closed Corner

Welded Corner

Break-Corner/Corner Trim

Corner Relief

Lofted Bend - Formed Method

Lofted Bend - Bent Method

Gusset

Swept Flange

Vent

Insert Forming Tool

Edit Forming Tool

Create Forming Tool

Design Library Cuts

Create Cuts

Converting a 3D Solid Into Sheet Metal

Converting a 3D Shelled Part Into Sheet Metal

Multi Sheet Part1 Creation

Multi Sheet Part 2 Creation

Assembly Creation

Unfold and Fold

Generating a Drawing View

Generating a Drawing View Of The Flat Pattern

Exporting 2D Files For Manufacturing

Creating Forming Tools

Sink

Body 1 - Base

Body 2 - Cover

Part1 - Housing

Part 2 - Door

Assembly - Electric Panel

COURSE 7: SOLIDWORKS: INTRODUCTION TO FINITE ELEMENT ANALYSIS (FEA) + CSWSA-FEA PREP

Instroduction

Simulation Add In and Options

New Study

Material

Fixture

Loads

Mesh and Model Simplification

Standard Mesh

Curvature Based Mesh

Mesh Control

Running Analysis

Geometry Modification

Chart Plots

Results Systematization

Compare Results

Separate Studies

Loadcase Manager

Conclusion

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Autem dolore, alias, numquam enim ab voluptate id quam harum ducimus cupiditate similique quisquam et deserunt, recusandae.

Introduction

Static Analysis

Full Model Analysis and Comparison

FE Types

Introduction

Surface - Geometry Preparation

Surface - Static Analysis

Surface - Conclusion

Sheet Metal - Introduction

Sheet Metal Analysis and Results Comparison

Introduction

Developing a CAD Model With Weldment Tools

Truss Model1: Results

Truss Model2: Analysis Preparation

Truss Model2: Results

Introduction

Bean vs Truss

Analysis Preparation

Results

Download Material

Question 1

Question 2

Question 3

Question 4

Question 5

Question 6

COURSE 8: SOLIDWORKS ADVANCED TOOLS AND TECHNIQUES

Dynamic Mirror Entities

Repair Sketch

Quick Snaps

Instant 2D

Rapid Sketch

Derived Sketch

3D Sketch

Equations

Example 1

Example 2

Exercises

Lofted Boss

Lofted Cut

Boundary Boss

Boundary Cut

Multi-body Part

Draft

Draft Types

Hole Wizard

Thread

Wrap

Helix, Spiral, and Composite Curve

Intersect

Instant 3D

Using Sketch by Multiple Features

Part Modification

Example 1

Example 2

Exercises

Advanced Mates

Mechanical Mates

Belt

Mirror Components

Assembly Features

Sub-assembly

In-Context Features and External References

Collision Detection

Replacing Part

Top-down Assembly

Example 1

Example 2

Exercises

Material and Density

Appearance

Scene

Camera

Lights

Rendering

Motion Study and Animation Wizard

Applying Motors

Adding Appearance and View Orientation

Walkthrough 1

Walkthrough 2

Introduction

Sketch Picture 1 and Extrusion

Sketch Picture 2 and Extrusion

Slot and Circular Hole

Fillet

Creating USB Slots

Text

Appearance and Rendering

Exercise

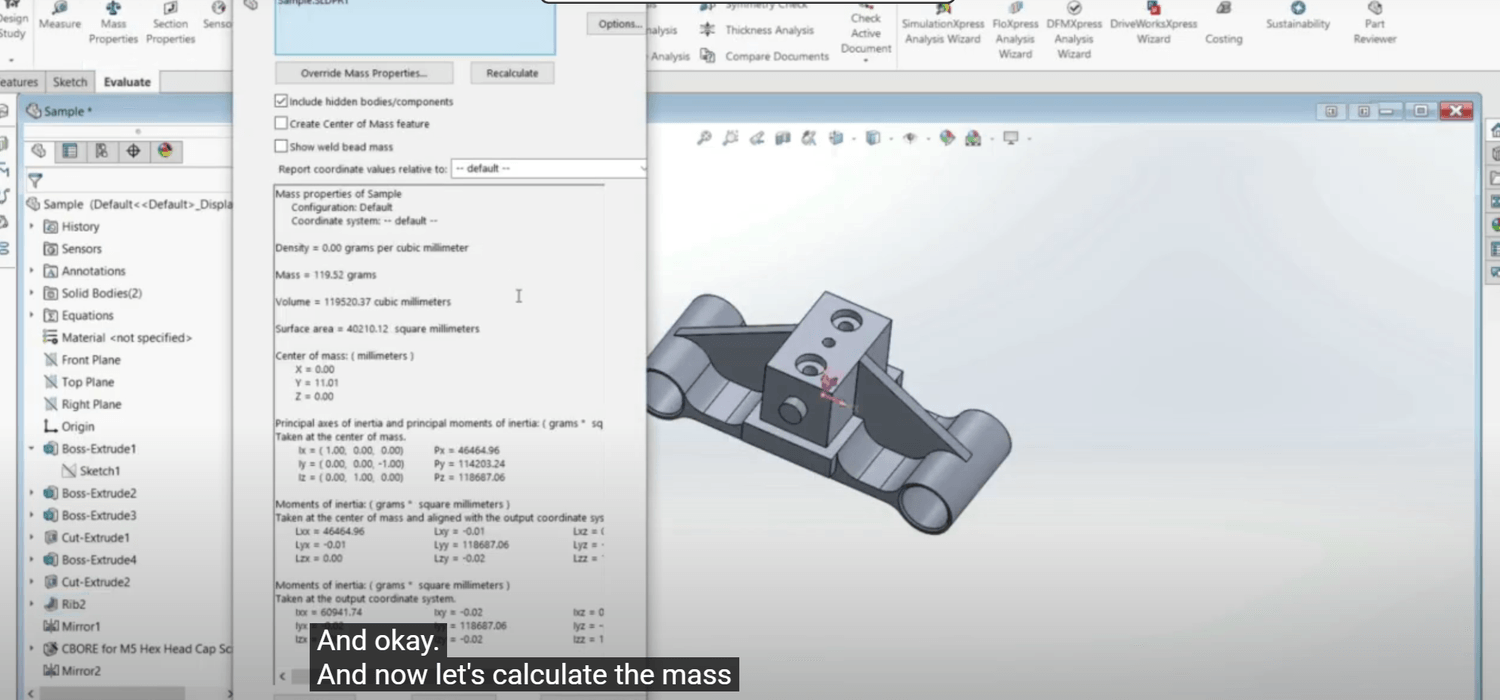

Mass Properties

Override Mass Properties

Measuring Tool

Inteference Detection

Compare Documents

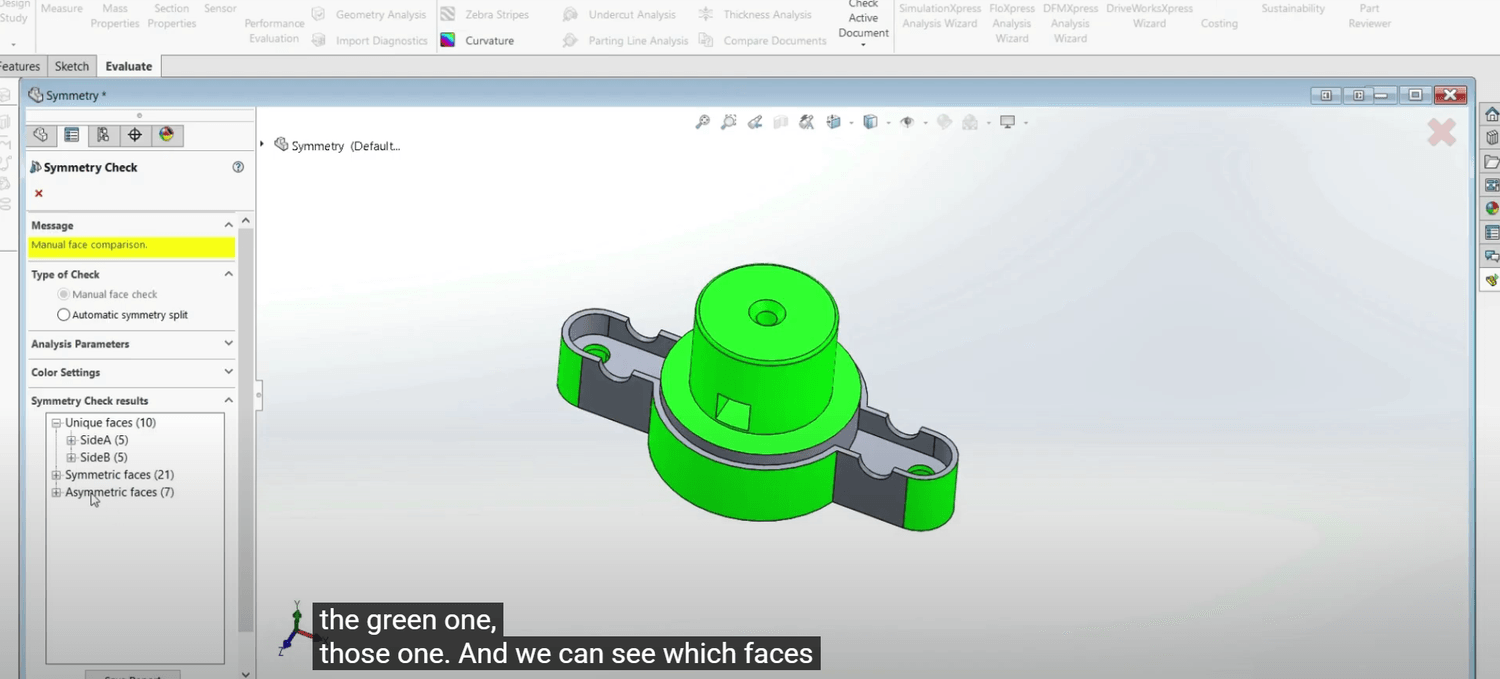

Symmetry Check

Part Reviewer

Assembly Visualization

Performance Evaluation

Compare Assembly

Check Active Document

Privacy policy | Terms of use | Cookies